Area C: Surface chemistry and reactivity

The projects of Area C will develop and investigate the chemical reactions occurring on the solid surface during the nucleation and individual growth steps of a new solid semiconductor phase by atomic layer deposition (ALD). Area C is articulated along three main axes:

- the understanding of requirements for successful nucleation and the design of responsive surfaces for controlled or patterned nucleation: C1 (Bachmann), C3 (Dube), C4 (Ng);

- the design of reactions for growing high-quality semiconductors on specific surfaces, with particular emphasis on deciphering the influence of substrate termination, surface ligands, and solvent on the characteristics of ALD growth: C1 (Bachmann), C2 (Hirsch);

- the investigation of reaction mechanisms, including the identification of adsorbed intermediates and the kinetics of surface reactions from molecular precursors: C4 (Ng), C5 (Libuda), C6 (Wisser).

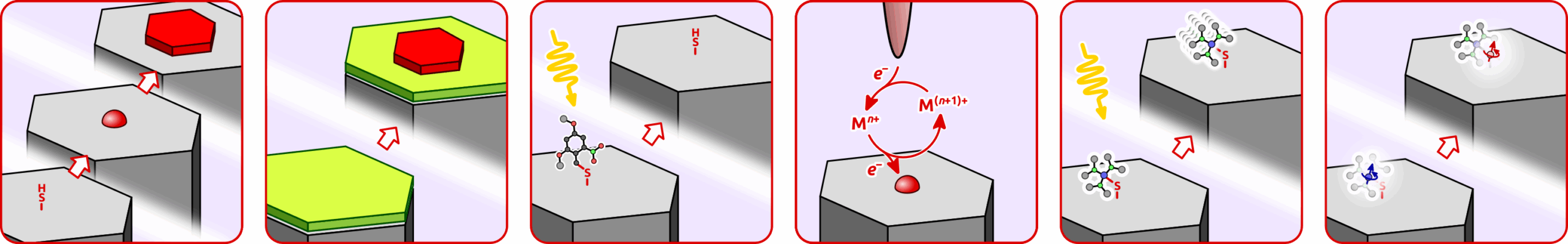

Classical thin film deposition methods yield one of three possible modes of nucleation and growth (island

formation, layer-by-layer, islands on wetting layer) depending on the energies of relevant interfaces: the

substrate / deposit interface and the deposit / vacuum interface. Of them, only the former can be adjusted

experimentally. Atomic layer deposition (ALD) offers an additional control option, since it uses molecular

chemistry to stabilize the latter interface at each step. What is more, in solution ALD (sALD) yet another

parameter becomes adjustable, namely the nature of the solvent and its interaction with the solid surface.

Key questions within this project:

How can substrate, precursors and solvent be exploited to modulate interfacial energies and

thereby control the deposit in ALD, and in sALD in particular?

Can the dimensionality of the semiconductor deposit be defined based on the experimental

nucleation and growth conditions?

We will tune the chemical identity of the substrate’s surface to define nucleation sites and vary the energy

of its interaction with the deposit. We will perform area-selective deposition on patterned substrate. The

comparison of gas-phase ALD with sALD will provide insight into the participation of solvent in the surface

chemistry. We will highlight how it modulates the reactivity of both the solid surface and the molecular

precursors. Inhibiting the reactivity on one facet shall induce two-dimensional growth.

Project leader: Prof. Dr. Julien Bachmann

C2 explores fundamental concepts fabrication and surface chemistry of semiconducting two-dimensional (2D) materials, namely TMDCs (MX2) and V-VI SCs (M2X3). The findings of this project will (i) elucidate basic principles of 2D materials reactivity, (ii) shape their electronic and chemical properties by structured surface patterning, and (iii) implement seed-controlled growth of layered heteroarchitectures (transition to smart 3D conductors). This will be central for both the formation of complex low-dimensional SCs and their implementation in future applications.

Key questions within this project

What are the inherent chemical properties and functionalization principles of 2D SCs?

How can efficient 2D surface modification be achieved?

Which unprecedented properties will these functionalized 2D material derivatives exhibit?

Which functionalization strategies can be harnessed for a covalent patterning of 2D surfaces via lithography or laser writing, and finally for constructing patterned 2D heterostructures?

Which chemical concepts are most promising to successfully promote seed initiated growth of vertical 2D heterostructures as new types of layered semiconductors in a controlled manner?

Project leader: Prof. Dr. Andreas Hirsch

Project C3 (Dube) designs and creates responsive surface-bound molecules for the control and spatially resolved light-triggering of nucleation ability, based on insight from C1. Organic molecules will be synthesized which feature one or even multiple ‘caged’ (masked) but photoreleasable functional groups. These groups will become reactive when released within an inert self-assembled monolayer (from F6). Beyond enabling direct patterning using classical photolithography methods, the combination of several photocages within one molecule will pave the way towards superresolution akin to the principles exploited in microscopy ― to be tested with C1 and F6. Theoretical insight will be provided by M2, M3, M4.

Project leader: Prof. Dr. Henry Dube

Project C4 (Ng) utilizes electrochemical techniques in a liquid environment to investigate the growth and properties of films and structures. Atomic force – scanning electrochemical microscopy (AFM-SECM) will provide insight into the growth and defect formation of 2D semiconductors. We will start with g/sALD TMDCs (C1) and exfoliated 2D TMDC layers (S4), followed by organic molecules and functionalized layers (C2, C3, F5). We explore the influence of defects and structural features toward (photo)electrochemical reactions and (photo)degradation of the semiconducting layers (complementing C5, S1) and testing models of film growth and defect formation (C5, C6, S2–S5, F1, M1–M4).

Project leader: Prof. Dr. Siow Woon Ng

Project C5 (Libuda) elucidates the fundamental reaction mechanisms, identifies surface reaction intermediates, and quantifies the kinetics of individual reaction steps, using in situ infrared spectroscopy and other in situ methods. The reactions designed and performed in C1, C2, C3, C4 from either the gas or solution phase will be investigated in various conditions, starting from ultraclean model surfaces to real interfaces (solid/gas and solid/liquid) to observe and quantify the adsorption and reaction of molecular precursors during nucleation and growth, complemented with other methods of surface characterization in C6, S1, S3, S5. The results will shed light onto the conversion of specific surface chemistries to defects within the solid deposit, in collaboration with S2, S4, M1, M2, M3, M4.

Project leader: Prof. Dr. Jörg Libuda

Project C6 (Wisser) applies solid-state nuclear magnetic resonance to identify and quantify physisorbed and chemisorbed reaction intermediates at the nucleation and growth stages of deposition, and to characterize the formation of a novel solid phase. The endeavour implies the development of methods to enhance the signal of specific heteronuclei of relevance to the surface functionalization schemes and the reactions developed in C1, C2, C3, F3, F4. Comparison will be made to other analytic techniques in C5, S3, S4. Project C6 will deliver a unique combined chemical and structural insight into the chemistry of solid deposition, to be interpreted in collaboration with M1, M3, M4.

Project leader: Dr. Dorothea Wisser